In January Nestlé announced that it will invest up to CHF 2 billion to lead the shift from virgin plastics to food-grade recycled plastics and to accelerate the development of innovative sustainable packaging solutions.

Building on its 2018 commitment to make 100% of its packaging recyclable or reusable by 2025, Nestlé will reduce its use of virgin plastics by one third in the same period whilst working with others to advance the circular economy and endeavor to clean up plastic waste from oceans, lakes and rivers.

Food quality and safety are paramount, and packaging plays a major role in assuring this. Most plastics are difficult to recycle for food packaging, leading to a limited supply of food-grade recycled plastics. To create a market, Nestlé is therefore committed to sourcing up to 2 million metric tons of food-grade recycled plastics and allocating more than CHF 1.5 billion to pay a premium for these materials between now and 2025. Nestlé will seek operational efficiencies to keep this initiative earnings neutral.

Packaging innovation, including new materials, refill systems and recycling solutions, is another key challenge on the path towards a waste-free future. In addition to its significant inhouse research through the Nestlé Institute of Packaging Sciences, the company will launch a CHF 250 million sustainable packaging venture fund to invest in start-up companies that focus on these areas.

These two initiatives come in addition to Nestlé’s major ongoing efforts in research, sourcing and manufacturing to make its packaging recyclable or reusable and contribute to its goal to achieve zero net greenhouse gas emissions by 2050. As part of the company’s packaging commitment and to increase transparency, Nestlé will continue to outline further initiatives and provide regular progress updates.

“No plastic should end up in landfill or as litter,” said Mark Schneider, CEO of Nestlé. “Making recycled plastics safe for food is an enormous challenge for our industry. That is why in addition to minimizing plastics use and collecting waste, we want to close the loop and make more plastics infinitely recyclable. We are taking bold steps to create a wider market for food-grade recycled plastics and boost innovation in the packaging industry. We welcome others to join us on this journey.”

“We are pleased to see Nestlé commit a CHF 2 billion investment toward creating a circular economy for plastics, alongside a reduction of its use of virgin plastic in packaging by one third by 2025. By eliminating the plastics we don’t need, innovating in areas like reuse models and new materials, and circulating the plastics we do need — also in more challenging food grade applications — we can create an economy where plastic never becomes waste. Achieving the commitments announced today will significantly contribute towards realizing this vision,” said Andrew Morlet, CEO, Ellen MacArthur Foundation.

Please find the official press release on nestle.com

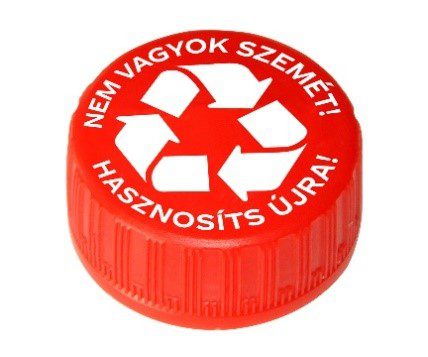

One of the aims of Coca-Cola’s global Zero Waste World strategy is to collect as many plastic bottles and aluminium cans by 2030 as the amount sold. To advocate selective garbage collection, the company launches a national

One of the aims of Coca-Cola’s global Zero Waste World strategy is to collect as many plastic bottles and aluminium cans by 2030 as the amount sold. To advocate selective garbage collection, the company launches a national  2050. Daikin’s business partners were also introduced to a range of new products and initiatives including the high efficiency, low GWP Daikin mini VRV 5 and the pioneering L∞P by Daikin scheme which reuses refrigerant for new VRV systems.

2050. Daikin’s business partners were also introduced to a range of new products and initiatives including the high efficiency, low GWP Daikin mini VRV 5 and the pioneering L∞P by Daikin scheme which reuses refrigerant for new VRV systems. market solutions that reduce the CO2 footprint of our customers. The key visual representing the VRV Summit consists of three leaves, which together highlight the three most important fields of action: innovation, circular economy and smart control.” – explained Bernard Dehertogh, head of commercial DX products at Daikin Europe.

market solutions that reduce the CO2 footprint of our customers. The key visual representing the VRV Summit consists of three leaves, which together highlight the three most important fields of action: innovation, circular economy and smart control.” – explained Bernard Dehertogh, head of commercial DX products at Daikin Europe.